Are you willing to launch your tights brand? Nowadays, tights are the most trendy bottom wear for women. Women are most likely to buy a pair of tights rather than a pair of jeans. Tights are comfortable and super easy to wear; maybe that’s the reason why they have gained huge popularity. Starting a tights business can be challenging but an exciting venture. Here are some essential tips which may help you start a tights business.

Do Tights Market Research

Before launching your tights, it is better to develop an idea about how your tights will make a mark in the market. There are tons of successful tights brands. You need solid reasons why consumers will prefer your tights over your competitors’. This process is critical for the brand’s successful future, yet it is pretty simple.

First, make sense of how you want your product to be. Second, determine your target customers, your customers’ needs, and issues they face with their tights. Also, know from where do they buy their tights. Then, from the data gathered, list out the brands trying to solve the same issues. Such brands can be your potential competitors. If a billion-dollar, well-developed brand happens to be your potential competitor, then you must look for different issues to solve. It is not a good idea to directly compete with a top brand on the same issue.

Examine the bestsellers of your competitors and look for any commonalities. It will give you an idea of what’s already in the market and what are opportunities you can exploit. This helps you develop innovative tights, better than your competitors.

Two major areas will consume your time and money: Manufacturing and Marketing.

Tights production manufacturing

To start the tights business, you will need a safe place to set up your manufacturing plant. The area of space depends on the size of your business. In the beginning, you can set up a micro-level plant in your home. Besides, you can hire a suitable apparel manufacturer to make the tights for you. In this setting, you do not have to set up a manufacturing plant, but the choice of manufacturer is extremely important. After you decide on the manufacturer, the following things will demand your attention:

1. Technology

Find out what technologies other brands are employing to make their tights. And choose the one that matches your needs and budget. Communicate the selected technology with your manufacturer.

2. Raw materials

Generally, the raw material for tights are fabrics that depend on the type of tights you want to manufacture. However, some common fabrics used in tights are:

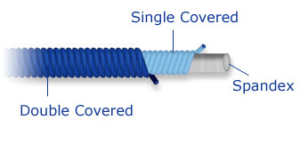

- Lycra

- Spandex

- Nylon

- Polyester

- Polyester blend

- Silk

- Cotton

3. Tights Design

Designing is a tricky process; that’s why it is better to consult with an apparel designer. Set measurements and dimensions of tights of different sizes and communicate such information with your manufacturer.

4. Tights Packing

Mainly, two types of packing are used for tights. There are cardboard packing and transparent plastic packing. In cardboard packing, you can add various manufacturing particulars like colour, size, company etc. Generally, individual pieces are packed separately. But for wholesale supply, multiple pieces can be packed together.

Marketing of Tights

Marketing and distribution are the major determinants of how much profit you make. To grow your sales, you need to focus on various promotional aspects during branding, product launching, and distribution. Hire a professional sales team to develop an efficient marketing strategy for your tights business.

Consider launching tights in a single city, build a small population of loyal customers, and expand smoothly to other cities. Appoint distributors or wholesalers to spread your business across other cities.

Here are a few marketing tips to increase the sales of your products:

1. Social Media

Social media is a cheap and excellent tool to boost sales. Use various social media platforms (Facebook, Twitter, Pinterest, etc.) to make your brand recognized and attract more customers. You can hire a creative agency or a local videographer to help you make Ads. The more creative the ads, the more impact they will have on the audience.

2. Website

You create a website of your brand and sell your tights online. Through the website, you can take orders from anywhere in the world. Moreover, to further expand the business you can create an e-store on different e-commerce platforms such as:

- Shopify

- Amazon

3. Friends and family

Spread the word among your friends and family about the launch of your tights business.

- Introduce them to your business, show them your products and tell them about the range of designs you have.

- Your friends and family can also be a marketing source, so impress them with your product range. Consider any marketing or business ideas they have.

4. Business cards

It is primitive but effective. Make decent business cards of your brand with contact and website printed on it. Business cards are intended to leave something with someone, so they have something to look back at it.

5. Distribute to local businesses

You can be a wholesaler and sell your products to small businesses, not directly to the customers. But being a wholesaler means you have to make tights in bulk amounts without a handsome profit in return.

6. Be your own billboard

Wear the tights you want to sell. It will not be very convincing if you are not wearing the product you are trying to sell. That’s why it is better to show your tights by wearing them and matching them with fitting tops. This will increase the confidence of in your products.

7. Consignment at other Storefront Businesses

Consignment means that you distribute the product to a retailer without being paid at that time. But you will get the payment at a predetermined future date, i.e., weekly, monthly, 90 Days. You should have an agreement in writing with the retailer and for large consignments, it is strongly suggested seeking legal advice to guarantee that your interests are secure.

The cost required to start a tights business

The cost to start a tights business depends on the size of your business. Here are some factors that may influence the cost required:

1. Location

A key factor in determining the cost of launching a tights brand is location. Business consultants and realtors can help you chose the ideal and profitable location for tights business.

2. Licenses and permits

To start a tights business, it is mandatory to get official licenses and permits in most countries. It may include building license, operational license, zonal permit, etc. There is a separate fee for each license which will add to the overall cost.

3. Size of the facility

It is also a major factor in determining the initial cost of the tights business. The larger facility will require more machinery and ultimately more numbers of workers, which will increase the overall cost.

4. Branding and marketing

Marketing is essential for the growth of the tights business. It requires the hiring of a special team for promotion purposes. There are many means to promote your products, from cheap to expensive. The type of marketing strategy you select will influence the budget.

5. Furnishing and equipping

Besides essential machinery and equipment for tights production, an investor must want the facility to look unique. The budget should also include the cost of the counter area equipment, store equipment, security cameras, furniture, fire alarms, and safety equipment.

6. Insurance

In many countries, you cannot start a tights business without having some basic insurance policy. The insurance amount will also be an addition to the overall cost. It is suggested to consult an insurance broker to assist you in getting the appropriate insurance coverage.

7. Fabrics

The cost of fabric used to prepare tights to depend on the kind and quality of fabric. High quality fabrics are expensive and will raise the budget accordingly.

8. Staff and workers

The hiring and training of staff and workers for your organization will cost money. Moreover, the salaries of employees will also influence the total cost to start the tights business.

Thriving is a successful tights manufacturer. You can click here to visit various tights we made in the past. >>

We hope that reading this article will help you start a tights business.