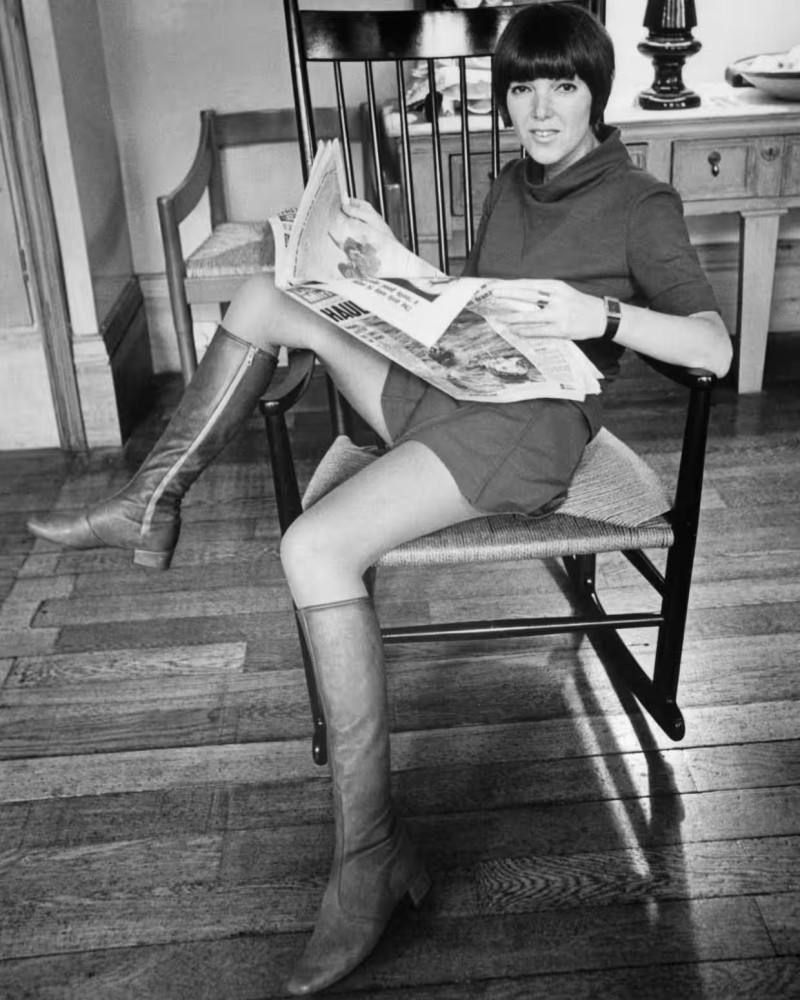

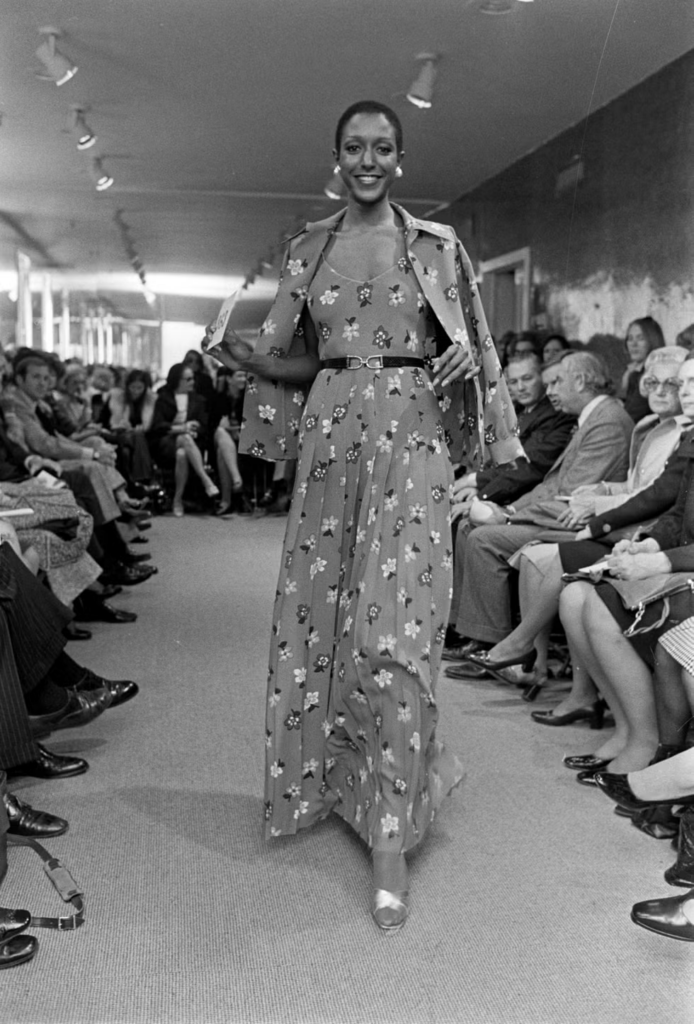

Before Mary Quant, running upstairs in a skirt or crying in mascara was nearly impossible. But everything changed in the 1960s. Mary Quant made miniskirts popular and designed practical clothes for working women. Now, a feature-length film directed by Sadie Frost explores her life and legacy.

The film follows her journey—from opening a Chelsea boutique to creating the world’s first global fashion superbrand. While today’s designers bring trends, Mary Quant completely changed how women dress.

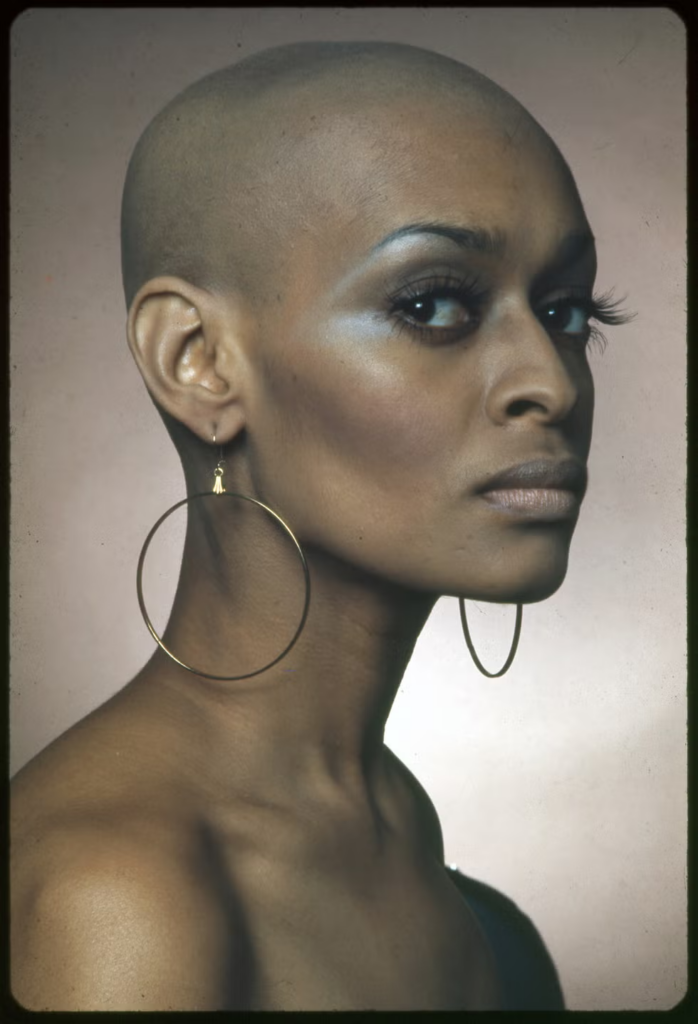

Thanks to her, women stopped following their parents’ beauty rules. Instead, they chose their own style. Her influence is still strong today.

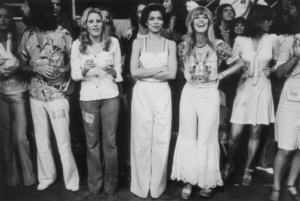

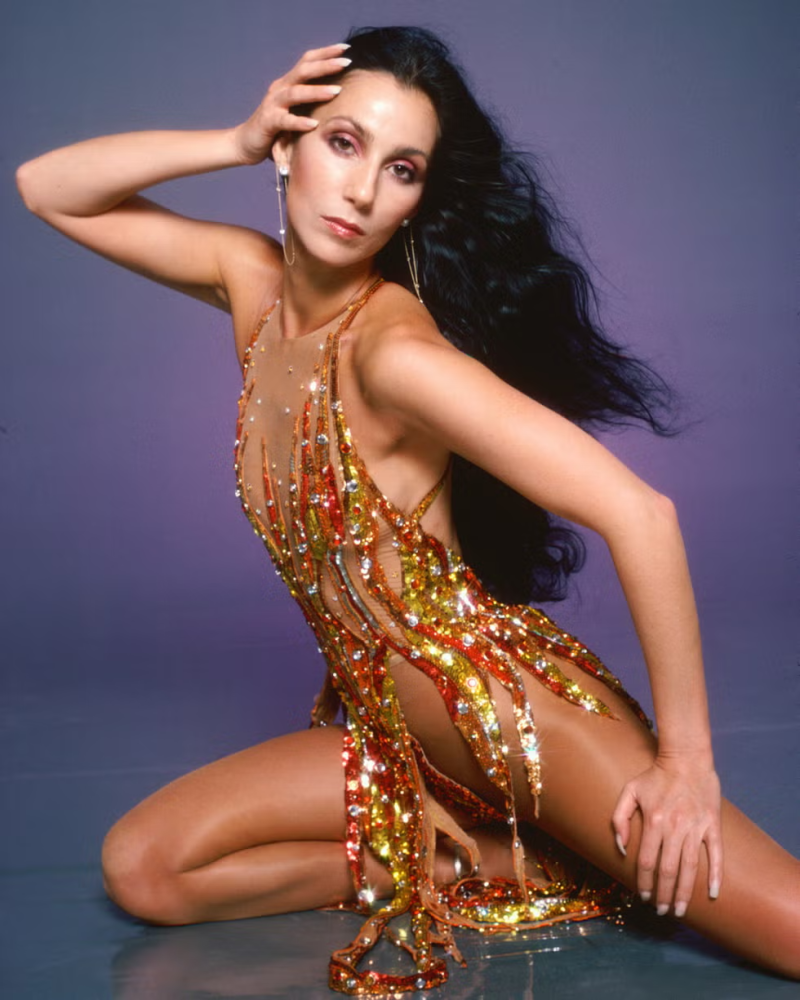

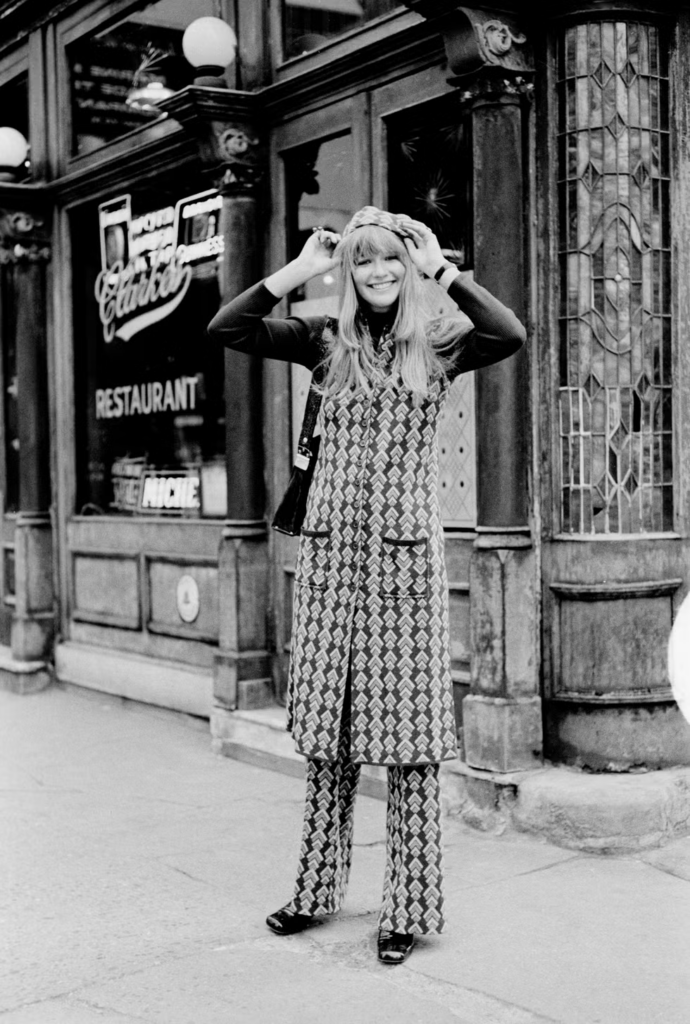

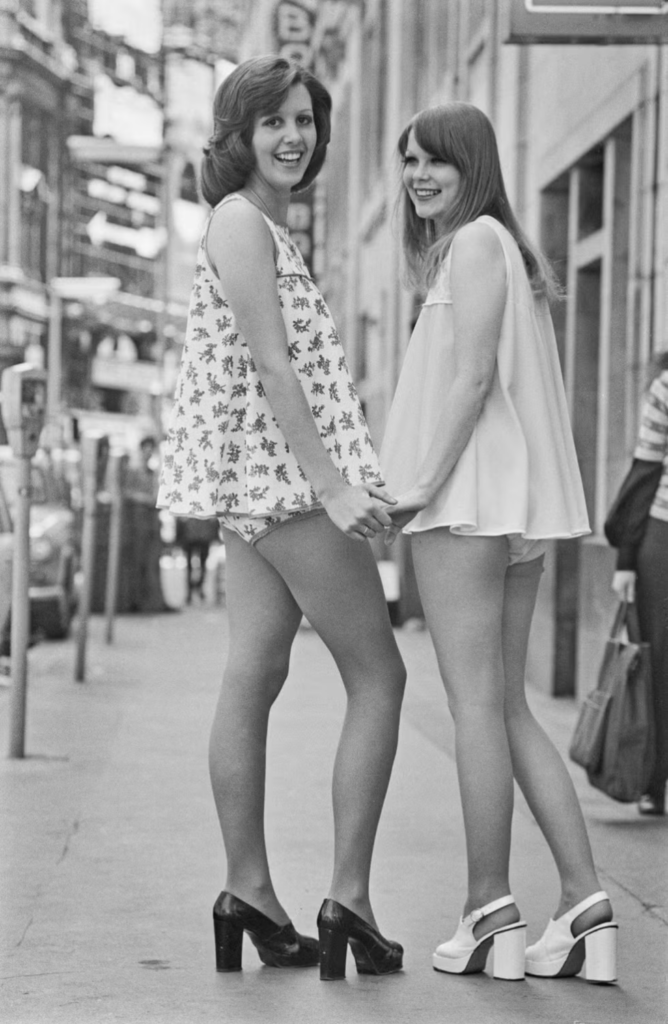

The miniskirt

It’s perfect timing that this look back at Mary Quant’s influence comes just as the miniskirt is making a huge comeback. Or maybe it’s a hopeful sign—life might be about to get better.

Quant is often credited with creating the miniskirt. She even named it after her favorite car, the Mini Cooper. To her, short skirts meant “life and tremendous opportunity.”

“She brought a party atmosphere,” says Jenny Lister, fashion curator at the Victoria and Albert Museum. “It was a renaissance. Young people met new friends, heard new music, and finally felt free to be themselves.”

Today, designers seem inspired by that same bold spirit. At recent Paris shows, thigh-skimming skirts were everywhere. Dior’s Maria Grazia Chiuri and Alaïa’s Pieter Mulier both embraced the look.

“I really like the energy of the younger generation,” said Chiuri. “The miniskirt shows that free, fearless spirit.”

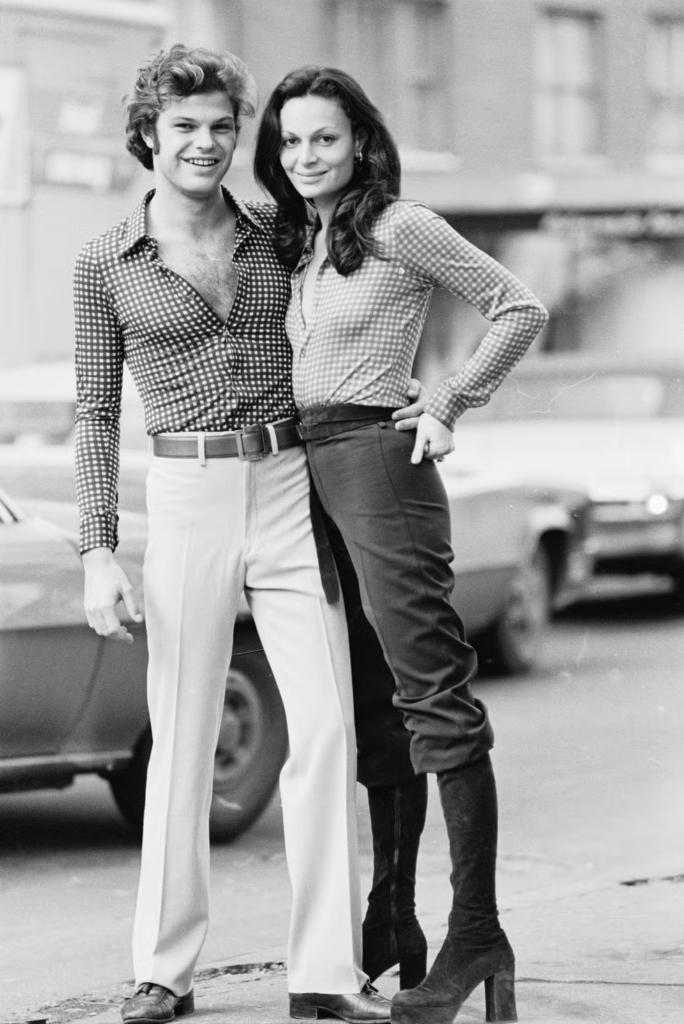

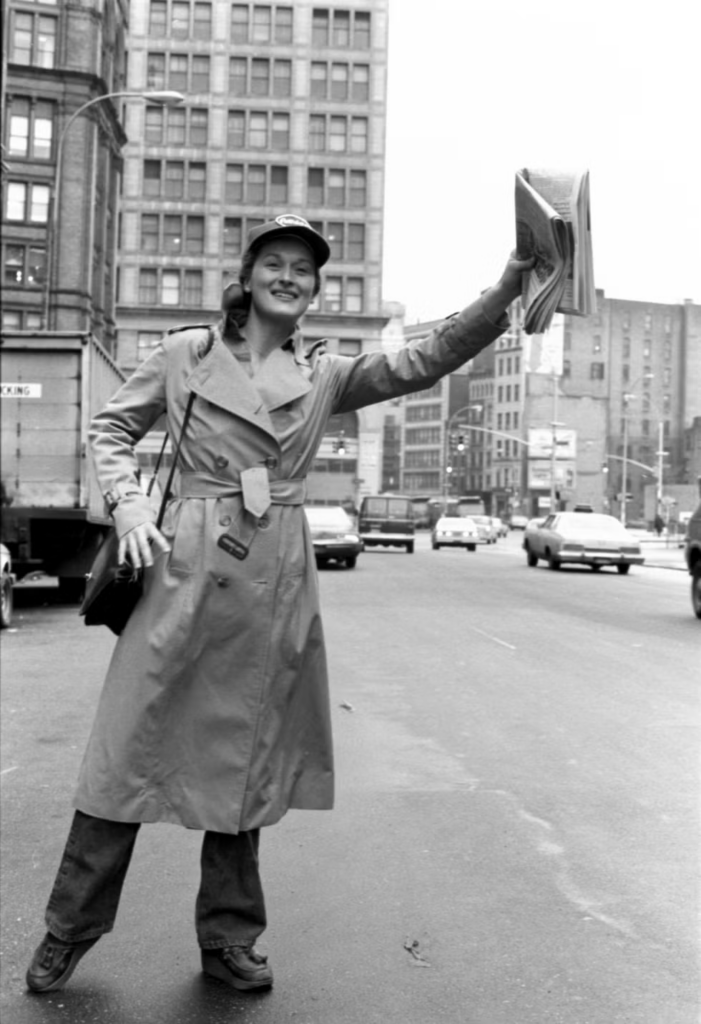

The original workwear

“Clothes are a statement about what one wants to be,” said Mary Quant. For her customers—many of them the first to use the contraceptive pill and plan both careers and families—freedom came first.

As her godson Jasper Conran says in Sadie Frost’s documentary, “The young working girl set the pace.” That’s exactly where modern workwear began.

Today’s dynamic, versatile style owes a lot to Quant. She made clothes that fit real life. “She was the first to make outfits you could run for the bus in,” says retail expert Jane Shepherdson.

Quant brought fashion and flexibility together. Her designs helped women move freely and live on their own terms.

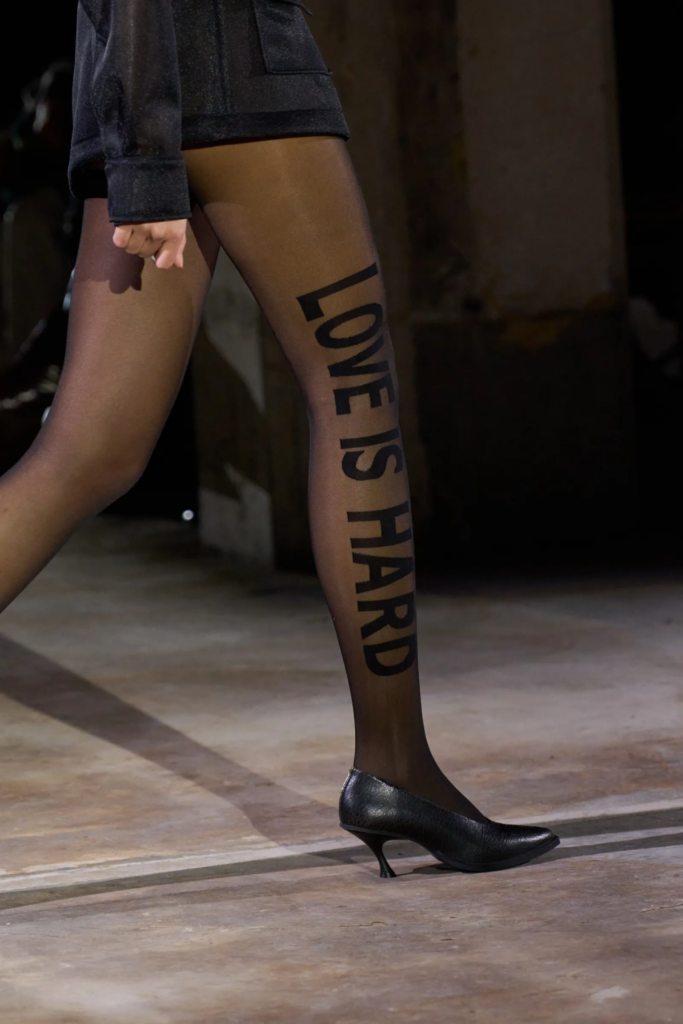

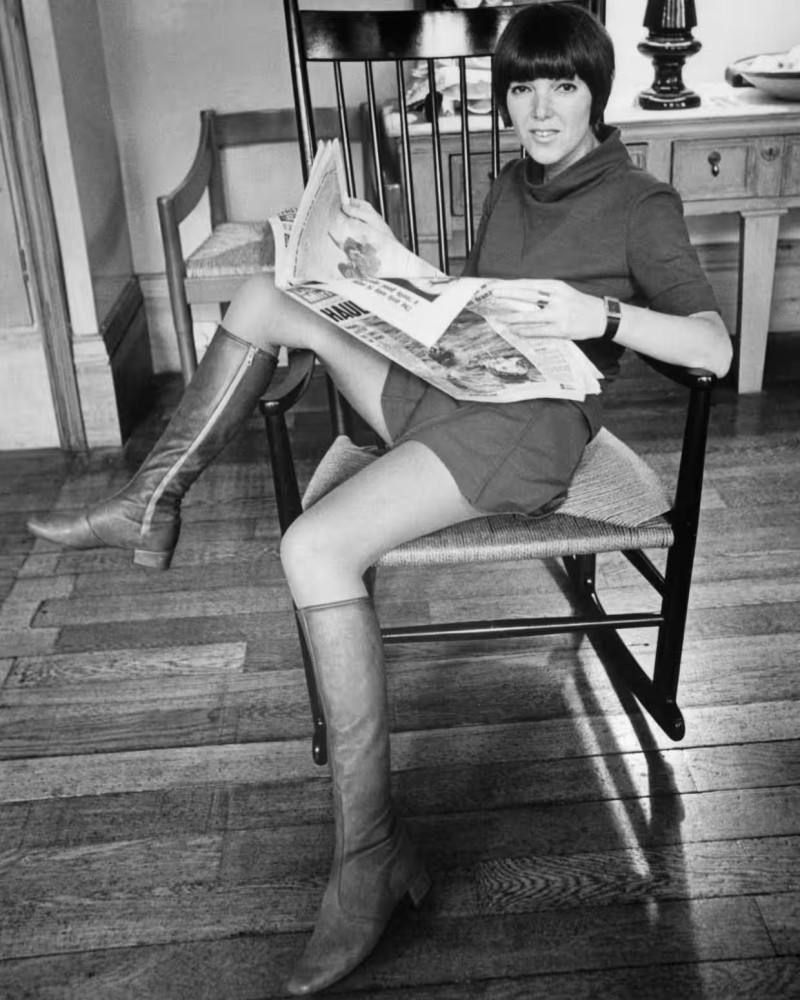

Saying no to stockings

Tights didn’t truly take off until Mary Quant made them mainstream. “Quant didn’t invent tights, but she made everyone aware of them,” explains Jenny Lister.

Looking for the perfect match for her bold skirts and dresses, Quant turned to hosiery. It became her secret weapon—and one of her most overlooked innovations.

By teaming up with the Nylon Hosiery Company, she designed tights in rich jewel tones to match her collections.

Now, tights are back in the spotlight. This season, McQueen brings sparkle with diamanté styles, while Falke launches bold tights in bright primary colors.

Clearly, Quant’s hosiery legacy still shapes fashion today.

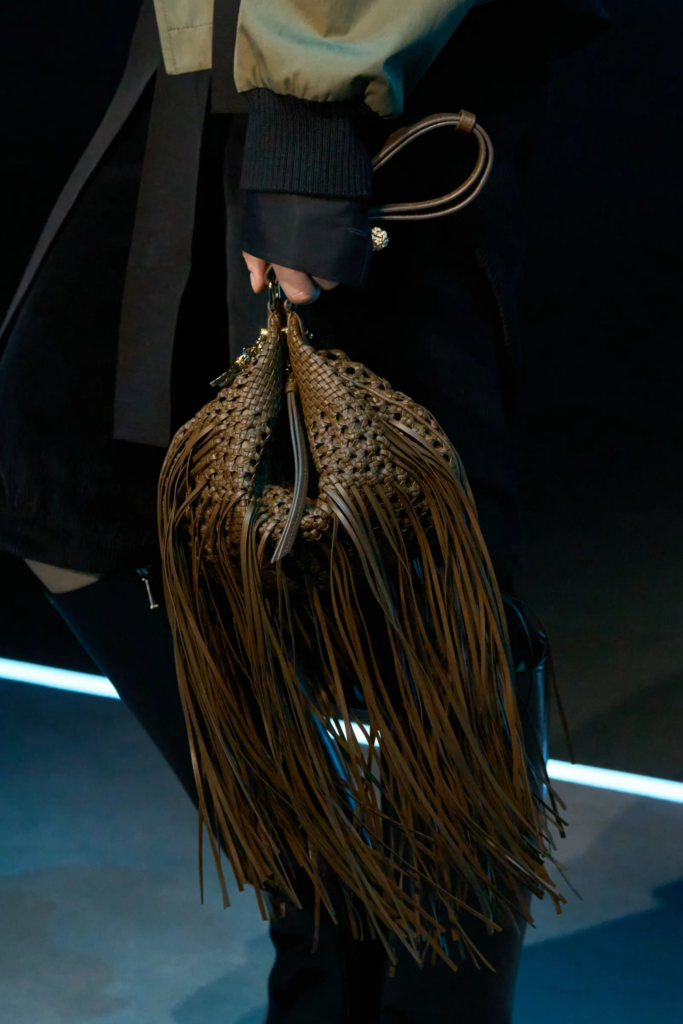

Pockets with everything

Next time you slip your phone into a dress pocket or tuck your hands into a jumpsuit at a party, thank Mary Quant. Even Victoria Beckham swears by this move.

Quant once said, “The pockets make the dress.” She saw their power long before the rest of fashion caught on.

While designing for women who wanted freedom from their mothers’ style, she made the pocket a symbol of modern living.

It wasn’t just practical—it was empowering. A place for lipstick, bus fare, or simply your hands when you needed confidence.

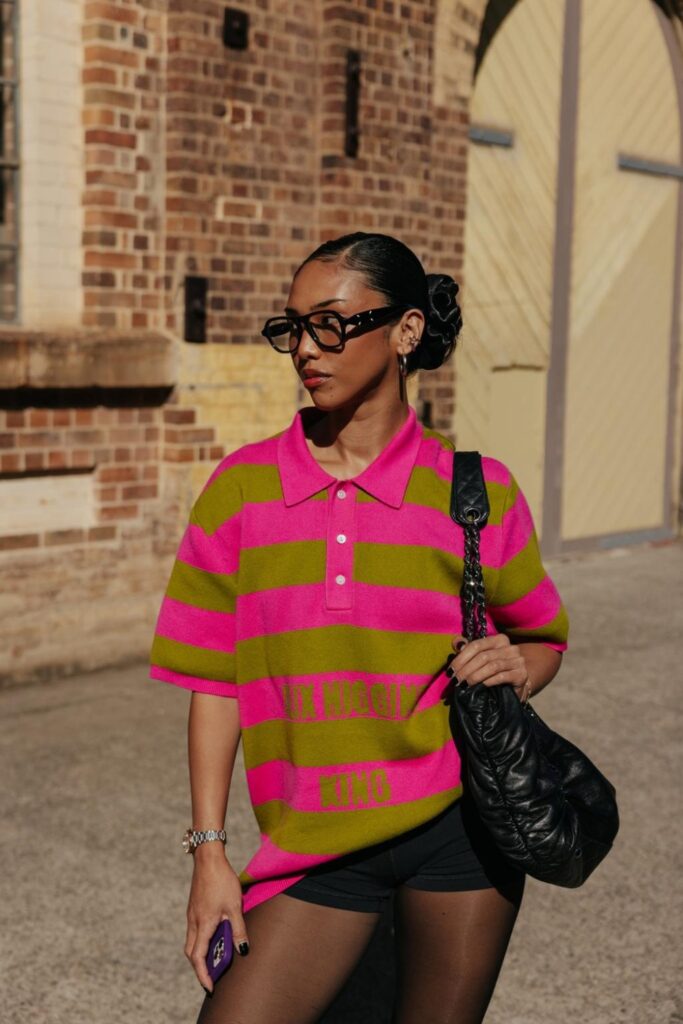

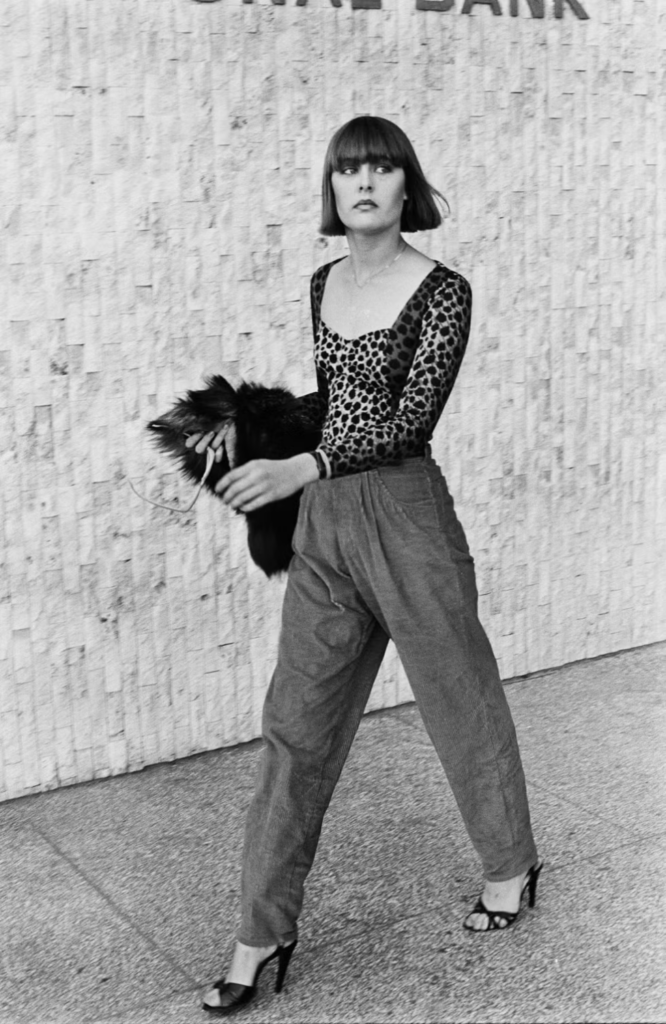

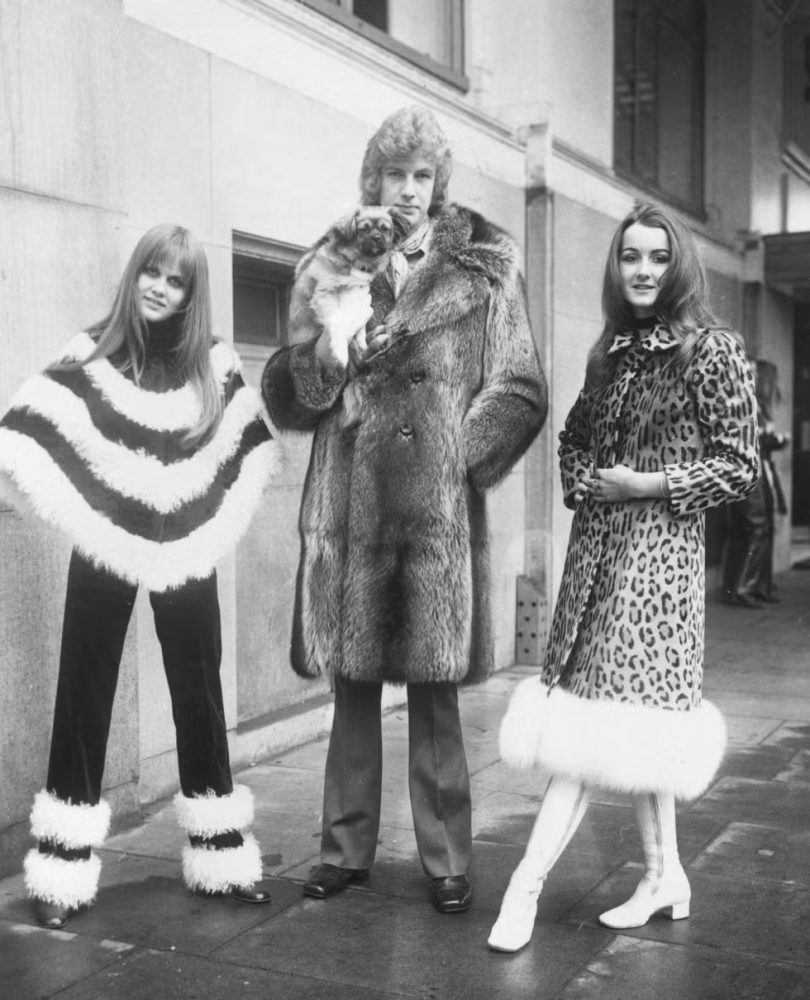

The ‘boyfriend’ fit

Gender-fluid fashion is often called the future, but Mary Quant was already there. She saw that men’s knitwear had the relaxed, casual feel she wanted.

So, she bought men’s suits from Harrods and redesigned them for women. Then, she worked with Scottish knitwear makers to create loose, easy cricket sweaters.

That laid-back, oversized look became a signature of her brand. Today, it’s still going strong.

Modern designers love those masculine fits. And Gen Z shoppers on Depop can’t get enough—cricket knits are now sweater dresses and resale gold.

Quant started a style revolution. She’d definitely be proud.

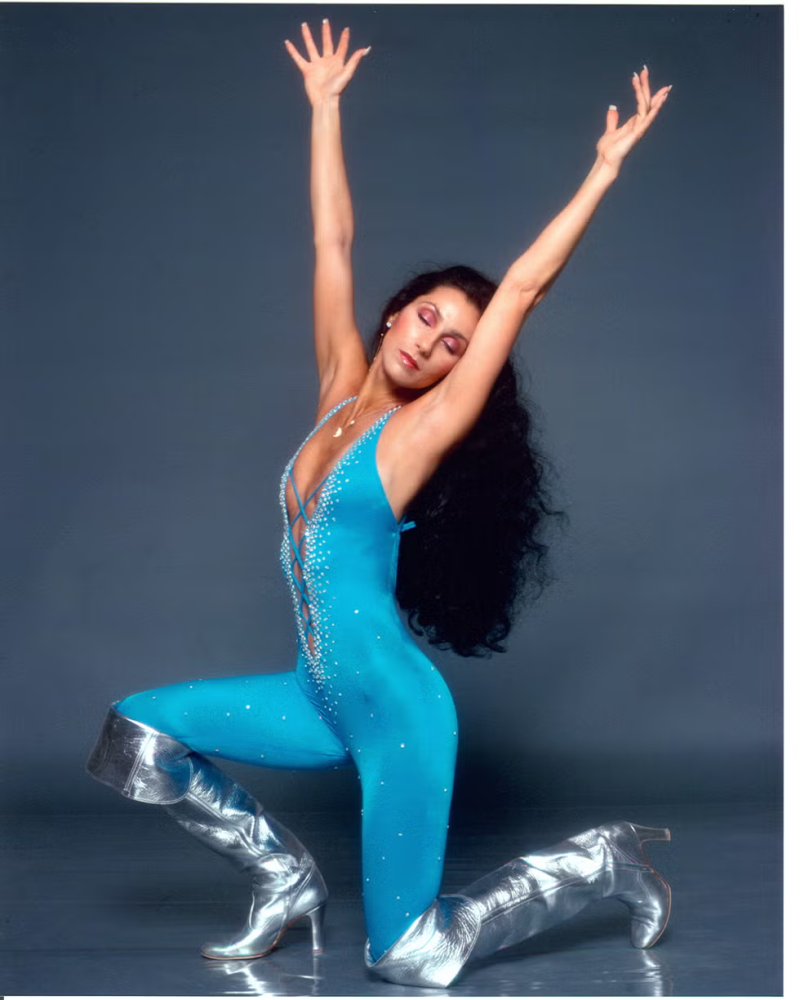

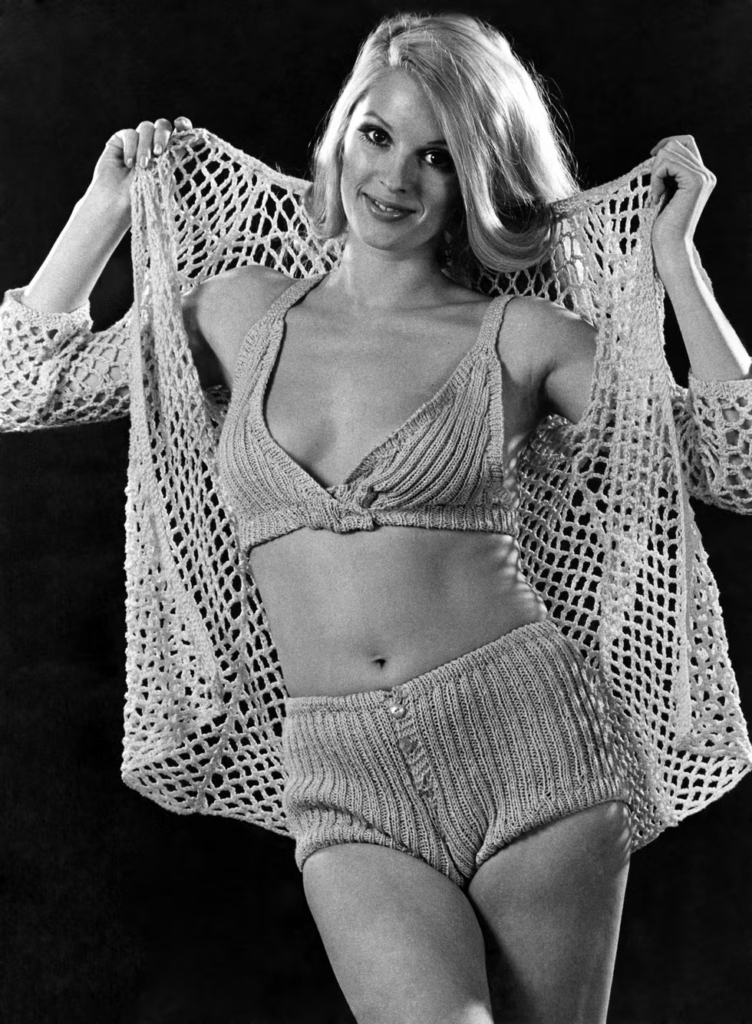

Athleisure 1.0

Our love for clothes you can wear on the sofa or to the gym peaked during the pandemic. But without Mary Quant, athleisure might not exist at all.

For Quant, jersey was the original Lycra. She was the first designer to back a fabric simply because it was soft, comfy, and wrinkle-free.

After a trip to the US, she discovered “house wear” and took it to the next level. In the late ’60s, she launched adult-sized babygrows—part tracksuit, part robe.

It was the first adult onesie. Cool, cozy, and way ahead of its time.

The skinny-rib sweater

Skinny-rib style became a fashion staple thanks to Mary Quant. In her 1966 biography, she recalls trying on an eight-year-old boy’s top—and loving the fit.

That fine-knit, ribbed sweater was a perfect match for her iconic pinafores.

Together, they created a fresh, youthful look that quickly caught on.

Soon, women around the world were copying the style. Quant had set another trend in motion.

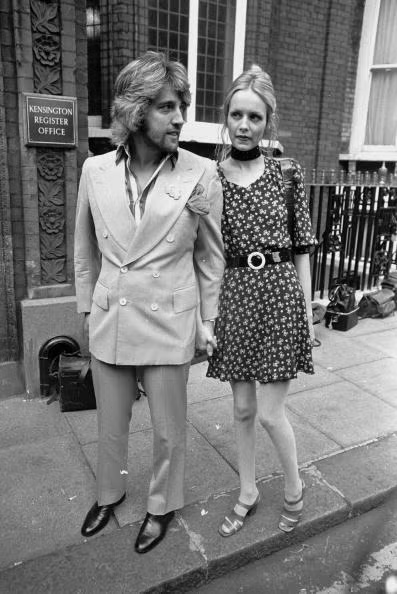

Party flats

For Mary Quant’s women—who worked by day and danced by night—flat shoes made perfect sense.

Before Quant, flats were seen as plain and practical. But she turned them into something stylish and glamorous.

“Everyone wearing trainers now is part of that same evolution,” says Jenny Lister.

Quant wanted shoes that were comfortable, practical, and still looked great. By doing so, she completed her modern look.

Most importantly, she helped women walk a new path—one of freedom and style.

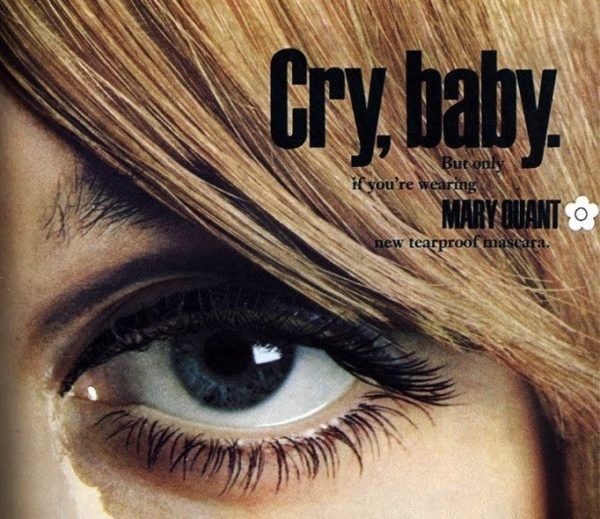

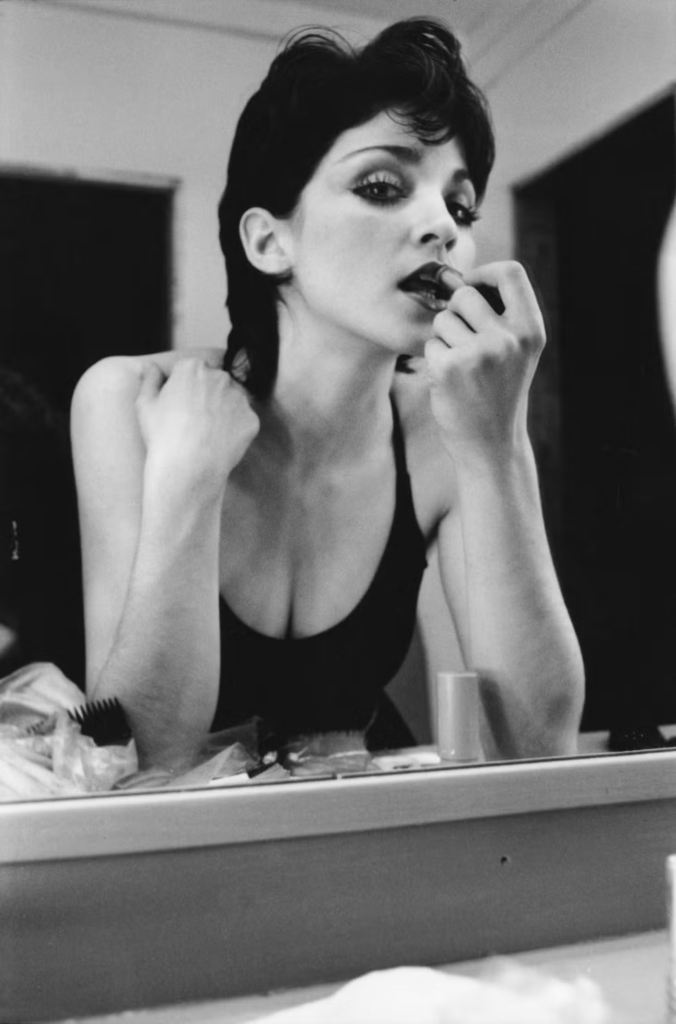

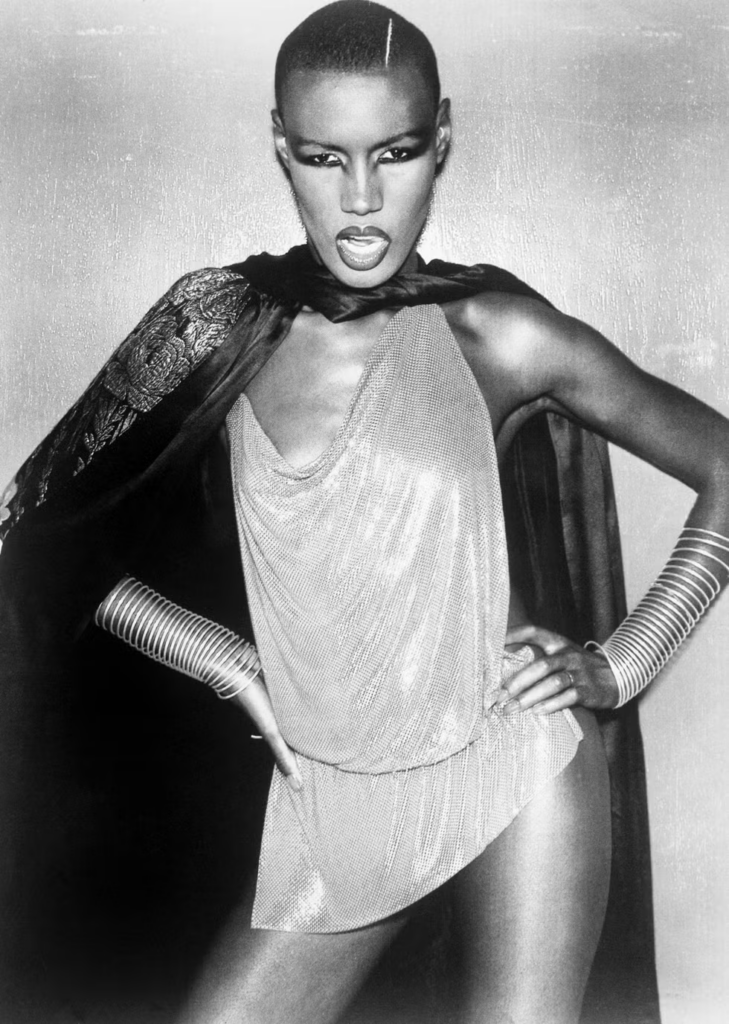

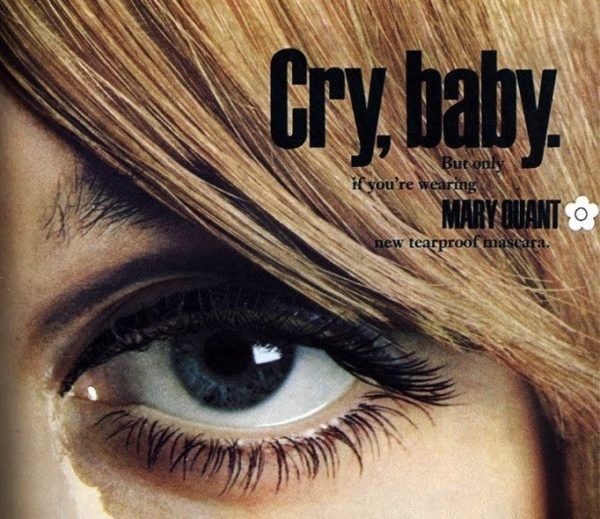

Fun-proof mascara

“Now that the clothes are different, the face was wrong,” Mary Quant said in 1968, realizing women needed makeup to match the look.

Her groundbreaking cosmetics line soon followed, with waterproof mascara at its heart—something totally new at the time.

With Quant’s designs, women could run for the bus, work all day, and even shed a tear—all while looking great.

“Quant eliminated the idea that women had to act a certain way,” says Jenny Lister. “Instead, she created space for people to be themselves.”