When 2022 Tour de France started from Copenhagen, audience gets the chance to enjoy very exciting races. Meanwhile, a new helmet appears in front of them. Some media define it as weird look thing. However, with the innovative sheer inner layer made by Thriving, the leading stockings supplier, the new helmet does help with the performance of riders.

According to Pierre Latour, this secret weapon can help save 26 seconds over a 40 km time trial. No wonder that is a quite obvious improvement considering the tight competition among riders. Wants to get more details about it? Lee, R&D manager of Thriving, the leading stockings supplier in China, will share the story with us.

The Headache for Riders

Traditional material for helmet’s inside part is foam with hole designs on both foam and helmet. This is for airflow and abstraction of heat in races.

Even with all these designs, the stickness between head and foam surface is still a headache. The sweat in races is the cause. Designers think adding an extra thin layer can be the cure. With creating more space for airflow, it can also help with tidying up rider’s hair. A perfect one-stone-to-kill-two-birds solution while the key point is to find the right material.

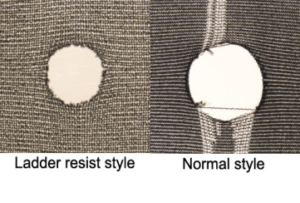

Stockings, to be exact, sheer stockings fabric is the number 1 choice from the beginning. However, when this was first tried in Europe,designers soon found that it won’t do the work. Sheer stockings are too fragile. In hosiery words, laddering or running. just as what people feel about it. The project was on hold for a while.

Thriving’s Involvement

” When received the request from clients, I think they made the right choice ” . Lee recalled the project with a satisfying smile. He is one of the veterans in stockings filed since 1995. Experiencing the peak and trough of the industry, Lee gained the instinct of finding the right answer to different requests. He chose ladder resist sheer stockings as the base fabric. This is a quite mature technology of Thriving who has been working with its Japanese yarn vendors from 2007. Marks & Spencer was the first brand that worked with Thriving for its product ranges(Check more on http://www.marksandspencer.com). With the special elastane used in it, ladder resist sheer stockings can prevent holes from laddering with still keeping the same stretchability and comfort(Thriving’s sheer stockings with this technology https://ytthriving.com/hosiery/). Most import thing for helmet layer is its durability. With lots of cutting and sewing, ladder resist fabric can ensure a reliable durability after all these manual operations. This makes a sheer but durable layer possible from a technical point of view.

Choosing the right fabric is the first step. Next move is to find the way of creating suitable shape for head and neck. It is not that easy to just knit a piece of stockings leg and used that as extra layer. “That will be just suitable for bank robbing!” Lee laughed for his explanation. “The volume of a leg is not large enough for head especially for a comfortable fitting to rider’s head. Therefore, we need to find other ways.”

Choosing the right fabric is the first step. Next move is to find the way of creating suitable shape for head and neck. It is not that easy to just knit a piece of stockings leg and used that as extra layer. “That will be just suitable for bank robbing!” Lee laughed for his explanation. “The volume of a leg is not large enough for head especially for a comfortable fitting to rider’s head. Therefore, we need to find other ways.”

The Process of Exploration

Lee soon found the panty part is the answer. In pantyhose stockings, panty part are two separate pieces joined together. The volume is sufficient for needs while still flexible enough for cutting and sewing. Lee cut a openning in the center for rider’s face. At the same time, he designed a closing on the two legs by extending the seaming from center to the very end. This made the initial prototype. “There are several rounds of adjusting sizes for fitting”, Lee said, “Good thing is sheer stockings fabric is so stretchy that a slight adjustment can do a big work. The process is not that torturing”

A new issue soon came to the table after trials. The extra layer was not able to bring enough air flow. Rider even felt the fabric was sticked to face more than the orginal foam surface. Lee put it on himself and tested the function in running for couple of times. Very quickly he figured out the reason. stockings were usually dyed with silicone softener for soft touch effect. However, in this layer product, silicone becomes a barrier for air flow as it created an invisible wall on the surface. By changing to a new eco-softener, Lee finally made the fabric effective for its designed function.

A new issue soon came to the table after trials. The extra layer was not able to bring enough air flow. Rider even felt the fabric was sticked to face more than the orginal foam surface. Lee put it on himself and tested the function in running for couple of times. Very quickly he figured out the reason. stockings were usually dyed with silicone softener for soft touch effect. However, in this layer product, silicone becomes a barrier for air flow as it created an invisible wall on the surface. By changing to a new eco-softener, Lee finally made the fabric effective for its designed function.

“Always no stop for innovation”, Lee says, “especially for stockings industry. I feel hard to admit that this industry is declining due to fashion trend but that is the fact. In this case, maybe only innovation can save the industry. That is why we still survive and stay as the leading stockings supplier”.